Choosing the right crane for a project starts with one critical question: how much can the crane safely lift? This is what crane capacity really means. It is not just a maximum weight number. Crane capacity depends on boom length, lifting radius, ground conditions, and how the lift is planned.

Many site delays and safety incidents happen because crane capacity is misunderstood or oversimplified. This guide explains crane capacity in clear, practical terms so engineers, planners, and project teams can make informed decisions before a lift begins.

Crane capacity refers to the maximum load a crane can lift safely under specific conditions. These conditions include boom configuration, lifting radius, counterweight setup, and ground bearing pressure.

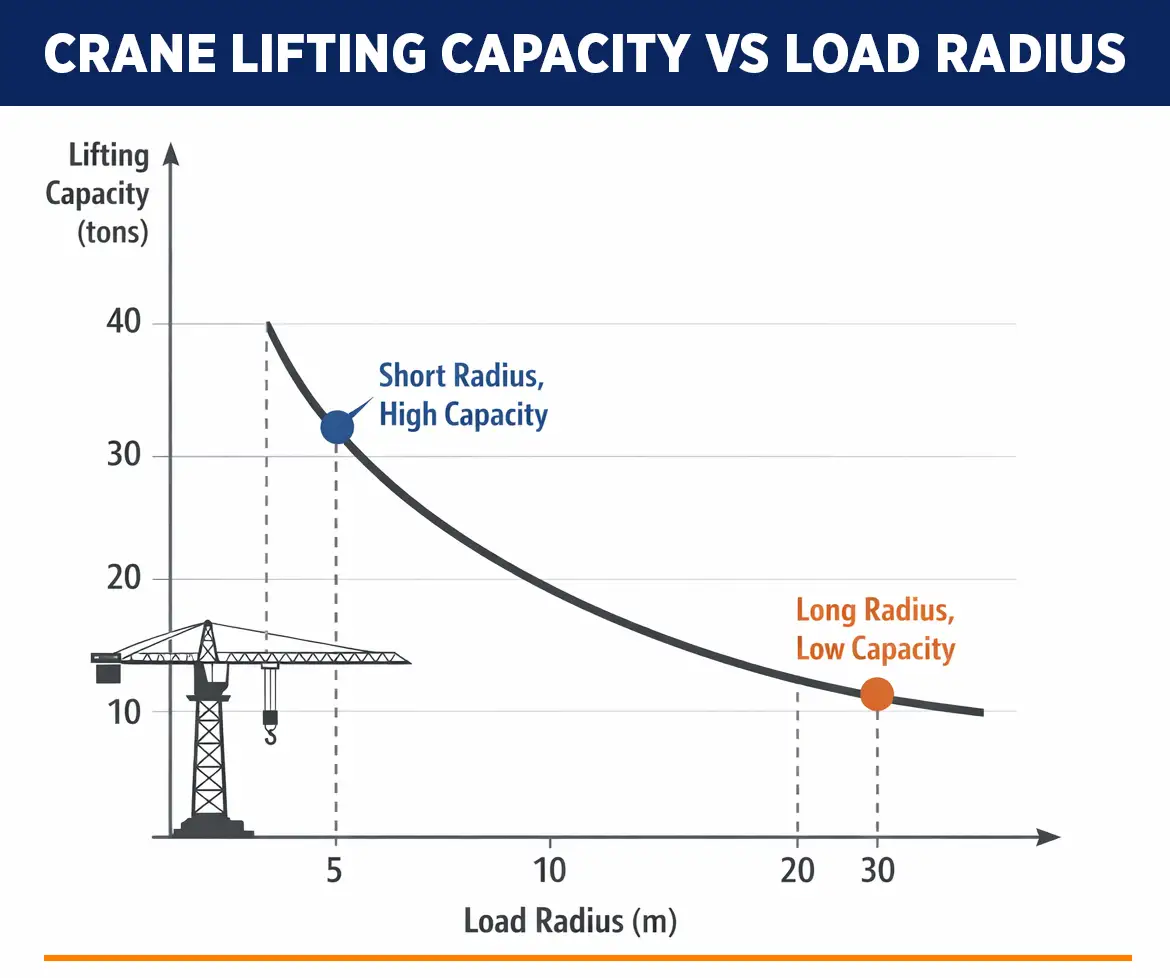

A common misconception is that a crane rated for 100 tons can lift 100 tons at any distance or height. In reality, that capacity applies only at a very short radius. As the boom extends or the load moves farther from the crane's center, the safe lifting capacity reduces.

In simple terms:

This is why load charts are essential for every lift.

Crane lifting capacity is directly linked to load radius, which is the horizontal distance between the crane's center and the load.

As the radius increases:

To remain safe, the allowable lifting capacity must decrease. This applies to all crane types, including mobile cranes, crawler cranes, and telescopic cranes.

Ignoring radius-based capacity is one of the most common causes of crane overload incidents.

A load chart is a technical document provided by the crane manufacturer. It shows the safe lifting capacity at different boom lengths and radii.

When reading a load chart, engineers look at:

Every lift should be planned using the load chart, not assumptions or past experience. Even cranes of the same tonnage can have very different capacity limits depending on configuration.

Crawler crane capacity is well suited for heavy and long-duration lifts. These cranes distribute load through tracks, which gives them excellent stability on uneven ground.

Typical crawler crane capacity ranges:

Crawler cranes maintain higher capacity at longer radii compared to wheeled cranes. This makes them ideal for:

However, crawler crane capacity still depends on boom length, superlift configuration, and ground bearing strength.

Telescopic crane capacity is designed for flexibility and quick mobilization. These cranes are commonly used in industrial sites, refineries, and urban construction.

Because telescopic cranes rely on outriggers, ground preparation and proper leveling play a major role in maintaining safe lifting capacity.

Jib crane capacity is usually much lower than mobile or crawler cranes. Jib cranes are designed for repetitive lifting within a fixed area, such as warehouses or workshops.

While jib cranes are efficient, they are not suitable for heavy or long-radius lifting. Understanding these limitations helps avoid misuse and equipment damage.

Several real-world conditions can reduce actual lifting capacity below chart values:

Professional lift planning always accounts for these variables.

Many lifting issues happen due to simple planning errors, such as:

Avoiding these mistakes significantly improves safety and project efficiency.

Instead of selecting a crane by tonnage alone, follow this approach:

This method ensures the selected crane operates well within safe capacity limits.

For a more detailed explanation of calculations, load charts, and lift planning basics, you can download our Crane Capacity Guide.

This guide is useful for site engineers, planners, and safety teams who want a quick reference during project planning.

Crane capacity is not just a technical specification. It is a safety boundary that protects people, equipment, and project timelines. Understanding how it works, and why it changes, helps teams avoid costly mistakes and unsafe lifts.

Whether you are planning a metro project, industrial erection, or maintenance lift, always base decisions on load charts, site conditions, and proper lift planning rather than assumptions.

A well-informed approach to crane capacity leads to safer, smoother, and more successful projects.