Boom Crane vs Crawler Crane: Key Differences, Site Fit & Real Project Insights

November 15, 2025

By Admin

When a project reaches the stage where lifts become the backbone of progress, high-rise glazing, precast segments, tower assembly, machinery placement, the discussion almost always circles back to two machines:

Boom Cranes and Crawler Cranes

It doesn't matter whether it's a metro corridor, refinery expansion, commercial tower, or industrial setup, choosing the wrong crane can slow down operations, alter sequencing, or restrict access. And unlike common “cost” comparisons floating around online, the real decision usually begins much earlier:

- What does the site demand, mobility or stability?

- Height or ground grip?

- Reach or load chart flexibility?

No pricing tables. No rental pitch.

Just real site-based insight, as engineers expect.

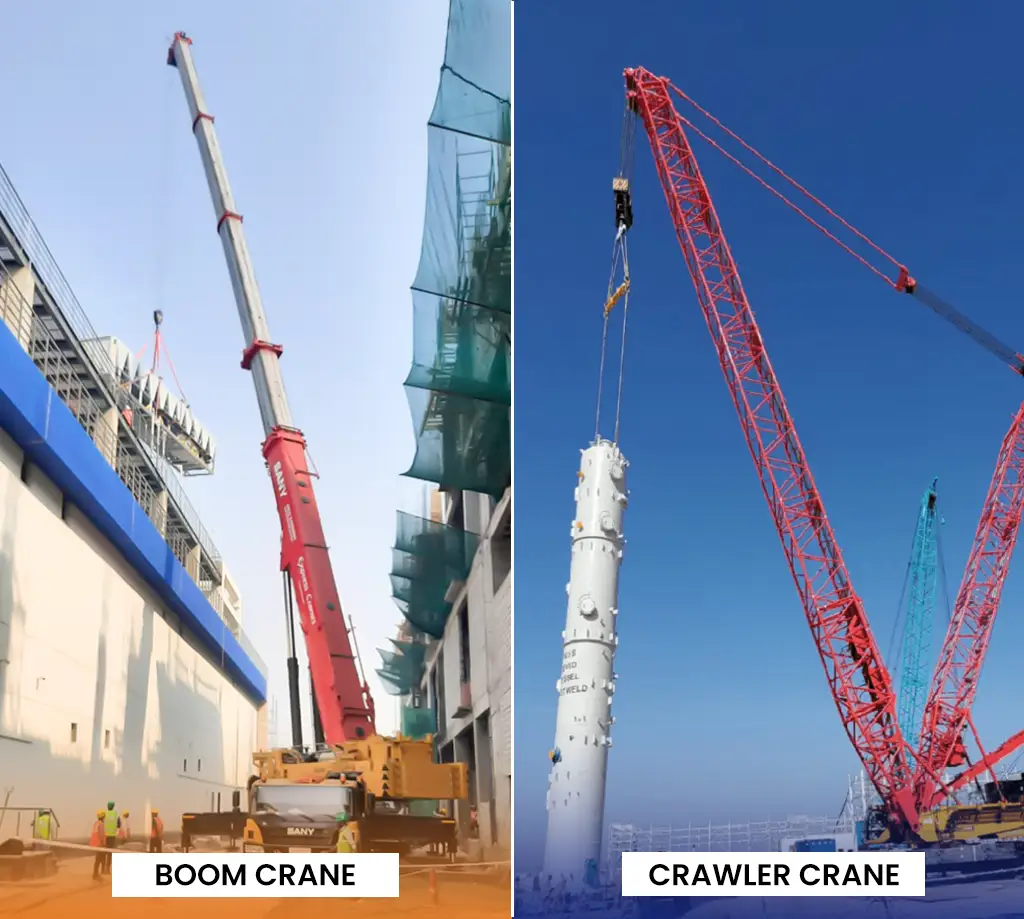

What Is a Boom Crane? (Understanding the Workhorse of Height & Reach)

A boom crane commonly known as a telescopic crane, uses a hydraulic boom that extends and retracts like sliding segments.

What makes it powerful:

Rapid setup

- arrives, stabilizes, and starts work quicklyHigh reach

- excellent for urban or vertical projectsFlexible movement

- drives into tight city sitesAdjustable boom length

- ideal for variable-height lifts

You'll see them frequently in:

- High-rise construction

- Tower glazing

- Equipment lifting inside city limits

- Flyover & metro segment handling (short-distance)

- Plant maintenance

- Wind tower auxiliary lifts

Its biggest strength?

Vertical reach with maneuverability.

What Is a Crawler Crane? (Built for Raw Stability & Heavy Lifts)

A crawler crane runs on tracks, no outriggers, no wheels.

What that gives you:

- Unmatched stability

- Superior load handling at low velocities

- Smooth movement under load

- Zero risk of tire slip

- Massive lifting charts (hundreds to thousands of tons)

You'll see them on:

- Metro rail piers

- Refinery modules

- Power plant boilers

- Bridge girder erections

- Large industrial plants

- Heavy civil projects

Its biggest strength?

Pure lifting capacity with ground grip.

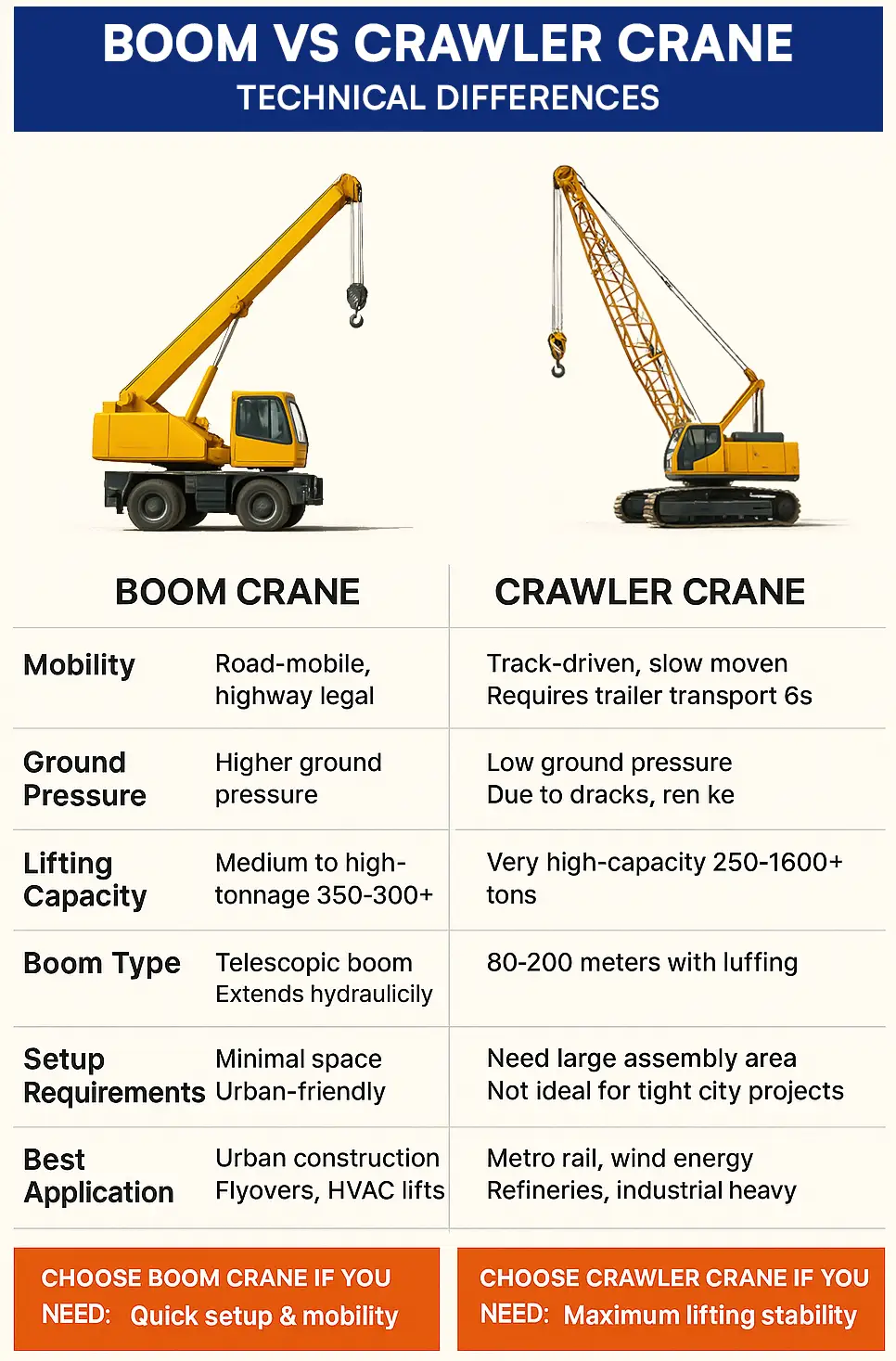

Boom Crane vs Crawler Crane: A Practical Engineering Breakdown

Think of this as a site-driven checklist, not a theoretical comparison.

1. Terrain

Site Type |

Better Choice |

Why |

| Soft soil |

Crawler |

Wide tracks distribute load |

| Urban concrete |

Boom |

Outriggers + mobility |

| Rocky uneven terrain |

Crawler crane |

Self-stability without outriggers |

2. Mobility Inside Site

- Moves fast, easy navigation, fits between obstacles

- Slow, long turning radius, needs planned pathways

If movement matters → boom wins.

If stability matters → crawler wins.

3. Lift Height vs Load Capacity

- Boom cranes win in height

- Crawler cranes win in load charts

High-rise = boom

Heavy industrial = crawler

4. Setup Conditions

Boom cranes:

- Faster setup

- Less assembly loading for boom operation

- Works in space-restricted areas

Crawler cranes:

- Long setup time (superlift, tracks, boom assembly)

- Needs to have considerable laydown area

5. Operator Control & Precision

- Telescopic booms = precision at height

- Lattice boom crawlers = stability and radius power

Real Case Study: Gurugram High-Rise Lift (900T Telescopic Equipment)

One of the most telling examples of crane selection came from a major lift in Gurugram at the Oberoi Site, where engineers needed to move heavy elements to a staggering height.

Project Requirements

- 900-ton telescopic boom crane

Main Boom:

78.2 metersLuffing Jib:

91 metersLuffing Jib:

91 meters

Why Not a Crawler Crane Here?

Because the site was:

- tight and urban

- surrounded by high-rise structures

- requiring rapid relocation inside a narrow footprint

A crawler crane would have needed:

- huge assembly space

- additional mobilization days

- blocked surrounding construction activities

Why the Boom Crane Won

- Reached 160 meters efficiently

- Stabilized on limited space using outriggers

- Required far fewer ground preparations

- Allowed repositioning without dismantling

Outcome

The lift was executed smoothly with minimal disruption to site movement, something only a telescopic boom could achieve in such an environment.

This case alone shows why terrain, space, and height matter more than capacity on paper.

When to Choose a Boom Crane (Engineer's Checklist)

Choose a boom lifting equipment if your site needs:

- High vertical reach

- Quick mobilization

- Tight working areas

- Multiple lift points at different heights

- Precision lifting at elevation

- City-based construction

Talk to a crane expert

When to Choose a Crawler Crane

Choose a crawler crane if your project involves:

- Heavy modules (industrial/refinery)

- Long-duration lifts

- Soft ground

- Infrastructure megaprojects

- Large-radius or complex arc lifts

- No strict space constraints

Final Decision: Which Crane Fits Your Site?

Here's the truth most guides avoid:

Neither crane is “better”, the site decides.

If you need:

- reach + mobility → Boom Crane

- load + stability → Crawler Crane

Engineers choose cranes based on:

- soil bearing capacity

- access limitations

- lift radius

- lift height

- load weight & distribution

- obstructions

- project timeline

And the Gurugram project proves that even massive lifts can favor a boom crane depending on the constraints.

Contact now

Final Decision: Which Crane Fits Your Site?

The debate isn't about boom vs crawler.

It's about finding the crane that matches the site, the lift, and the operational environment.

This blog gave a practical, real-world comparison backed by an actual project scenario, helping engineers, supervisors, and project managers decide with confidence.